| M1: General | |||

| Date of first acceptance | February 1980 | Total acceptances | 2,374 |

| Manufacturer | Chrysler Corp. | Crew |

|

| M1: Dimensions | |||

| Combat weight | ~120,000lbs ~54,000kg |

Height over .50cal MG | 113.6" 288.5cm |

| Length without gun | 311.7" 791.7cm |

Gun overhang forward | 72.8" 185cm |

| Width over skirts | 144.0" 365.8cm |

Tread | 112.0" 284.5cm |

| Ground clearance | 17.0" 43.2cm |

Fire height | 74.5" 189cm |

| Turret ring diameter | 85.0" 216cm |

Ground pressure, zero penetration | 13.3psi .936kg/cm² |

| M1: Armament | ||||||

| Type | Mount | Ammunition | Traverse | Max traverse rate | Elevation | Max elevation rate |

| 105mm Gun M68A1 | Combination mount in turret | 55 rounds (25 ready) |

360° (manual and electrohydraulic) |

40°/sec | +20° to -10° (manual and electrohydraulic) |

25°/sec |

| .50cal M2HB MG | Cupola on turret | 900 rounds (90 ready) |

360° (manual and electric) |

-- | +65° to -10° (manual) |

-- |

| 7.62mm M240 MG | Coaxial to 105mm gun | 10,000 rounds (4,800 ready) |

360° (manual and electrohydraulic) |

40°/sec | +20° to -10° (manual and electrohydraulic) |

25°/sec |

| 7.62mm M240 MG | Skate mount on loader's hatch | 1,400 rounds | 265° sector of fire (manual) |

-- | +65° to -35° (manual) |

-- |

| Aiming equipment | ||||||

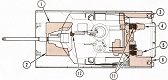

| Gunner's primary and auxiliary sights for gunner; gunner's primary sight extension and commander's weapon sight for commander | ||||||

| Rangefinder | ||||||

| Laser | ||||||

| Stabilizer | ||||||

| Azimuth and elevation | ||||||

| Night vision | ||||||

| TIS for gunner's primary sight and TC's extension, image intensifying periscope AN/VVS-1(V)2 for driver | ||||||

| M1: Armor |

| Assembly |

| Welding |

| Hull |

| Rolled homogeneous steel and composite armor arrays |

| Turret |

| Rolled homogeneous steel and composite armor arrays |

| M1: Automotive | |||||

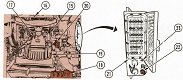

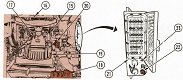

| Engine | Avco Lycoming AGT-1500; free shaft power gas turbine with two spool gasifier and recuperator | ||||

| Horsepower | Net: 1,232@3,000rpm Gross: 1,500@3,000rpm |

Torque | Net: 3,800 ft-lb@1,000rpm Gross: 3,934 ft-lb@1,000rpm |

Fuel capacity | 505gal 1,910L |

| Transmission | Allison X1100-3B, 4 ranges forward, 2 reverse | ||||

| Steering | Hydrostatic, T-bar | ||||

| Brakes | Hydraulic-mechanical, multiple disc | ||||

| M1: Suspension | ||

| Type | Road wheels | Track return rollers |

| Torsion bar | 7 independently sprung dual/track | 2 single/track |

| Drive sprockets | Idlers | Shock absorbers | 11-tooth rear drive | Dual compensating at front of track | On first 2 and last road wheels/track |

| M1: Track | |||||||

| T156 | |||||||

| Center guide, double pin, integral rubber pad | |||||||

| Width | 25" 64cm |

Pitch | 7.625" 19.37cm |

Shoes/track | 78 | Ground contact length | 180.1" 457.5cm |

| M1: Performance | |||

| Max level road speed | 45mph 72kph |

Max trench | 108" 274cm |

| Max grade | 60% | Max sideslope | 40% |

| Max vertical obstacle | 49" 120cm |

Min turning diameter | Pivot |

| Max fording depth | 48" 120cm |

Cruising range | ~275mi ~443km |

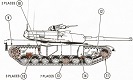

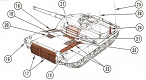

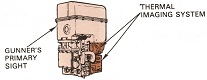

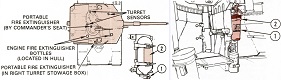

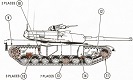

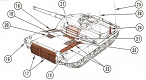

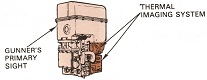

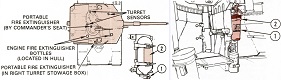

The driving force behind the development of the M1 Abrams was crew survival, and the tank's shape comes from composite armor developed towards this purpose. Special armor is also used in the forward track skirts. Of the fifty-five 105mm rounds, three were kept on the turret floor in spall-resistant covers, eight were stowed in an armored compartment in the hull behind the engine bulkhead, and the rest were stowed in the turret bustle behind armored blast doors. Blowoff panels in the hull ammunition compartment and the turret bustle vented ammunition explosions away from the crew compartment. The TC's hatch incorporated an open protected, or umbrella, position, which allowed visibility while still providing overhead protection. The gunner's primary sight included a day sight, the thermal imaging sight, laser rangefinder, and an extension for the TC so he could view what the gunner was seeing. The M1 was equipped with a digital ballistic computer that calculated firing solutions based on lead, cant, wind, range, gun barrel droop, and manually-entered variables such as atmospheric pressure, temperature, and ammunition temperature. The M1's drive sprocket was fitted with a retaining ring to help reduce early tanks' tendency to throw tracks due to rapid direction changes or the accumulation of dirt between the track and rear sponson.

| IPM1: General | |||

| Date of first acceptance | October 1984 | Total acceptances | 894 |

| Manufacturer | General Dynamics Land Systems | Crew |

|

| IPM1: Dimensions | |||

| Combat weight | ~122,000lbs ~55,300kg |

Height over .50cal MG | 113.6" 288.5cm |

| Length without gun | 311.7" 791.7cm |

Gun overhang forward | 72.8" 185cm |

| Width over skirts | 144.0" 365.8cm |

Tread | 112.0" 284.5cm |

| Ground clearance | 17.0" 43.2cm |

Fire height | 74.5" 189cm |

| Turret ring diameter | 85.0" 216cm |

Ground pressure, zero penetration | 13.5psi .950kg/cm² |

| IPM1: Armament | ||||||

| Type | Mount | Ammunition | Traverse | Max traverse rate | Elevation | Max elevation rate |

| 105mm Gun M68A1 | Combination mount in turret | 55 rounds (25 ready) |

360° (manual and electrohydraulic) |

40°/sec | +20° to -10° (manual and electrohydraulic) |

25°/sec |

| .50cal M2HB MG | Cupola on turret | 900 rounds | 360° (manual and electric) |

-- | +65° to -10° (manual) |

-- |

| 7.62mm M240 MG | Coaxial to 105mm gun | 10,000 rounds | 360° (manual and electrohydraulic) |

40°/sec | +20° to -10° (manual and electrohydraulic) |

25°/sec |

| 7.62mm M240 MG | Skate mount on loader's hatch | 1,400 rounds | 265° sector of fire (manual) |

-- | +65° to -35° (manual) |

-- |

| Aiming equipment | ||||||

| Gunner's primary and auxiliary sights for gunner; gunner's primary sight extension and commander's weapon sight for commander | ||||||

| Rangefinder | ||||||

| Laser | ||||||

| Stabilizer | ||||||

| Azimuth and elevation | ||||||

| Night vision | ||||||

| TIS for gunner's primary sight and TC's extension, image intensifying periscope AN/VVS-1(V)2 for driver | ||||||

| IPM1: Armor |

| Assembly |

| Welding |

| Hull |

| Rolled homogeneous steel and composite armor arrays |

| Turret |

| Rolled homogeneous steel and composite armor arrays |

| IPM1: Automotive | |||||

| Engine | Avco Lycoming AGT-1500; free shaft power gas turbine with two spool gasifier and recuperator | ||||

| Horsepower | Net: 1,232@3,000rpm Gross: 1,500@3,000rpm |

Torque | Net: 3,800 ft-lb@1,000rpm Gross: 3,934 ft-lb@1,000rpm |

Fuel capacity | 505gal 1,910L |

| Transmission | Allison X1100-3B, 4 ranges forward, 2 reverse | ||||

| Steering | Hydrostatic, T-bar | ||||

| Brakes | Hydraulic-mechanical, multiple disc | ||||

| IPM1: Suspension | ||

| Type | Road wheels | Track return rollers |

| Torsion bar | 7 independently sprung dual/track | 2 single/track |

| Drive sprockets | Idlers | Shock absorbers | 11-tooth rear drive | Dual compensating at front of track | On first 2 and last road wheels/track |

| IPM1: Track | |||||||

| T156 | |||||||

| Center guide, double pin, integral rubber pad | |||||||

| Width | 25" 64cm |

Pitch | 7.625" 19.37cm |

Shoes/track | 78 | Ground contact length | 180.1" 457.5cm |

| IPM1: Performance | |||

| Max level road speed | 41.5mph 66.8kph |

Max trench | 108" 274cm |

| Max grade | 60% | Max sideslope | 40% |

| Max vertical obstacle | 49" 120cm |

Min turning diameter | Pivot |

| Max fording depth | 48" 120cm |

Cruising range | ~275mi ~443km |

The IPM1 was equipped with heavier armor protection, and beefed up suspension components, transmission, and final drives to deal with the increased weight. The change in the final drive ratio reduced the tank's top governed speed. A new detachable stowage rack was also included on the rear of the turret.

| M1A1: General | |||

| Date of first acceptance | August 1985 | Total acceptances | 5,572 |

| Manufacturer | General Dynamics Land Systems | Crew |

|

| M1A1: Dimensions | |||

| Combat weight | ~130,000lbs ~59,000kg |

Height over .50cal MG | 113.6" 288.5cm |

| Length without gun | 311.7" 791.7cm |

Gun overhang forward | 75.2" 191cm |

| Width over skirts | 144.0" 365.8cm |

Tread | 112.0" 284.5cm |

| Ground clearance | 17.0" 43.2cm |

Fire height | 74.5" 189cm |

| Turret ring diameter | 85.0" 216cm |

Ground pressure, zero penetration | 14.4psi 1.01kg/cm² |

| M1A1: Armament | ||||||

| Type | Mount | Ammunition | Traverse | Max traverse rate | Elevation | Max elevation rate |

| 120mm Gun M256 | Combination mount in turret | 40 rounds (17 ready) |

360° (manual and electrohydraulic) |

40°/sec | +20° to -10° (manual and electrohydraulic) |

25°/sec |

| .50cal M2HB MG | Cupola on turret | 1,000 rounds (100 ready) |

360° (manual and electric) |

-- | +65° to -10° (manual) |

-- |

| 7.62mm M240 MG | Coaxial to 120mm gun | 7,200 rounds (2,800 ready) |

360° (manual and electrohydraulic) |

40°/sec | +20° to -10° (manual and electrohydraulic) |

25°/sec |

| 7.62mm M240 MG | Skate mount on loader's hatch | 3,600 rounds (200 ready) |

265° sector of fire (manual) |

-- | +65° to -35° (manual) |

-- |

| Aiming equipment | ||||||

| Gunner's primary and auxiliary sights for gunner; gunner's primary sight extension and commander's weapon sight for commander | ||||||

| Rangefinder | ||||||

| Laser | ||||||

| Stabilizer | ||||||

| Azimuth and elevation | ||||||

| Night vision | ||||||

| TIS for gunner's primary sight and TC's extension, image intensifying periscope AN/VVS-1(V)2 for driver | ||||||

| M1A1: Armor |

| Assembly |

| Welding |

| Hull |

| Rolled homogeneous steel and composite armor arrays |

| Turret |

| Rolled homogeneous steel and composite armor arrays |

| M1A1: Automotive | |||||

| Engine | Avco Lycoming AGT-1500; free shaft power gas turbine with two spool gasifier and recuperator | ||||

| Horsepower | Net: 1,232@3,000rpm Gross: 1,500@3,000rpm |

Torque | Net: 3,800 ft-lb@1,000rpm Gross: 3,934 ft-lb@1,000rpm |

Fuel capacity | 505gal 1,910L |

| Transmission | Allison X1100-3B, 4 ranges forward, 2 reverse | ||||

| Steering | Hydrostatic, T-bar | ||||

| Brakes | Hydraulic-mechanical, multiple disc | ||||

| M1A1: Suspension | ||

| Type | Road wheels | Track return rollers |

| Torsion bar | 7 independently sprung dual/track | 2 single/track |

| Drive sprockets | Idlers | Shock absorbers | 11-tooth rear drive | Dual compensating at front of track | On first 2 and last road wheels/track |

| M1A1: Track | |||||||

| T156 | |||||||

| Center guide, double pin, integral rubber pad | |||||||

| Width | 25" 64cm |

Pitch | 7.625" 19.37cm |

Shoes/track | 78 | Ground contact length | 180.1" 457.5cm |

| T158 | |||||||

| Center guide, double pin, replaceable rubber pad | |||||||

| Width | 25" 64cm |

Pitch | 7.625" 19.34cm |

Shoes/track | 78 | Ground contact length | 180.1" 457.7cm |

| M1A1: Performance | |||

| Max level road speed | 41.5mph 66.8kph |

Max trench | 108" 274cm |

| Max grade | 60% | Max sideslope | 40% |

| Max vertical obstacle | 49" 120cm |

Min turning diameter | Pivot |

| Max fording depth | 48" 120cm |

Cruising range | ~289mi ~465km |

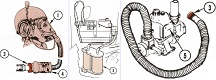

The M1A1 was fitted with a new turret armed with a 120mm gun equivalent to the Rheinmetall design found in Germany's Leopard 2. The ammunition stowage was reduced with the larger 120mm rounds, and the ammunition stowage on the turret floor was eliminated. Six rounds are stowed in the hull, with the remainder in the turret bustle. During production, the design of the rear track skirt was changed and the track retaining ring was deleted. Late-production M1A1s had holes in the turret roof for the installation of a commander's independent thermal viewer, which showed up on the M1A2. Also introduced during the production run was an eye-safe carbon dioxide laser that was able to operate under the same conditions as the gunner's TIS. The driver of the M1A1 was provided with a mechanical override for the engine and transmission's protective shutdown measures in 1986. This allowed the driver to operate the tank when the engine's management system would otherwise have shut the engine and transmission down, which would be a potentially dangerous situation in battle. This system was known as the shift hand actuated fuel transmission system (SHAFTS), and allowed the engine to work up to 400hp. The M1A1 was also fitted with an overpressure NBC system, and a microclimate cooling system cooled the crewmembers, but not the entire crew compartment. An external auxiliary power unit (EAPU) that would power the tank's systems without using the fuel-hungry gas turbine engine was initially attached to the right rear of the hull, and then a smaller model was mounted in the turret bustle rack.

Starting in October 1988 after 2,329 M1A1s had been produced, steel-encased depleted uranium (DU) was added to the tank's armor. Tanks with DU armor were designated M1A1 HA (Heavy Armor), and 2,140 were manufactured. A pulse-jet system for cleaning the engine air filters was also introduced, freeing crewmen from the task of removing and manually cleaning the filters. A second-generation DU armor array was later introduced into production, yielding the M1A1 HA+. DU armor was retrofitted to most of the M1A1s built before the armor was added to the production line.

M1A1s also underwent overhaul to factory standards in an effort to reduce maintenance costs, and this program was dubbed the Abrams Integrated Management (AIM) program. Some M1A1 AIMs were provided with the with the FBCB2 (Force XXI Battle Command Brigade and Below) Blue Force Tracker for identifying and transmitting the locations of friendly and enemy forces. From 2009, M1A1 AIMs were improved with more potent side turret armor, a tank-infantry phone mounted on the right rear of the hull, as well as upgraded sensors. These vehicles were called M1A1 SA (Situational Awareness). In 2012, M1A1 SAs started receiving a stabilized commander's weapon station. A digital applique command and control package was installed in 108 M1A1s starting in 2000, resulting in the M1A1D. The M1A1Ds were mothballed in 2004.

When the Marines acquired the M1A1 to replace their aging M60A1s, their requirements led to a tank with more tie-down points, mounting points for a deep-water fording kit, and a position locating system. These features were incorporated in the production line starting in November 1990 no matter to which service the tanks were sent, and M1A1s with these features and the depleted uranium armor were unofficially dubbed M1A1 HC, for Heavy Common. Marine M1A1s mount a different smoke grenade launcher system than Army tanks, and the M1A1 HC also saw use of a turret bustle-mounted external auxiliary power unit. The Marines awarded a contract to equip their M1A1s with a second-generation thermal sight and a high-resolution color display unit in the Firepower Enhancement Package (FEP) program. Marine M1A1s were upgraded with features found on the M1A1 SA like the stabilized commander's weapon station and tank-infantry phone, as well as Marine-specific programs like a suspension upgrade to endure a weight of 77 tons (70 metric tons).

Upgrade kits were ordered for the M1A1 in 2006. These kits, dubbed Tank Urban Survivability Kits (TUSK), involved adding an armored shield for the loader's rooftop machine gun, a thermal sight for the loader's MG, and XM19 Abrams reactive armor tiles (ARAT) arranged on the hull side in two rows of 16 tiles. The driver received a new harness and seat that was attached to the hull roof instead of the floor to help prevent mine shock injuries. Drivers were also given a thermal viewer that could be installed in the center periscope housing, and the TC's .50cal MG was also provided with a thermal sight. A tank-infantry phone was mounted on the rear hull, and a mount for another .50cal MG was attached to the gun mantlet above the 120mm gun to provide an option besides the main gun when trying to prevent collateral damage. Called the counter sniper/antimaterial mount (CSAMM), a 200-round ammunition box was part of this package. Due to the threat from improvised explosive devices (IEDs) and mines, a blast-deflecting V-shaped armor plate was installed on the hull bottom. The plate was 200mm (7.9") thick and weighed 2,998lb (1,360kg).

| M1A2: General | |||

| Date of first acceptance | December 1992 | ||

| Manufacturer | General Dynamics Land Systems | Crew |

|

| M1A2: Dimensions | |||

| Combat weight | ~139,000lbs ~63,100kg |

Height over .50cal MG | 113.6" 288.5cm |

| Length without gun | 311.7" 791.7cm |

Gun overhang forward | 75.2" 191cm |

| Width over skirts | 144.0" 365.8cm |

Tread | 112.0" 284.5cm |

| Ground clearance | 17.0" 43.2cm |

Fire height | 74.5" 189cm |

| Turret ring diameter | 85.0" 216cm |

Ground pressure, zero penetration | 15.4psi 1.08kg/cm² |

| M1A2: Armament | ||||||

| Type | Mount | Ammunition | Traverse | Max traverse rate | Elevation | Max elevation rate |

| 120mm Gun M256 | Combination mount in turret | 42 rounds (18 ready) |

360° (manual and electrohydraulic) |

40°/sec | +20° to -10° (manual and electrohydraulic) |

25°/sec |

| .50cal M2HB MG | Cupola on turret | 900 rounds | 360° (manual) |

-- | Manual | -- |

| 7.62mm M240 MG | Coaxial to 120mm gun | 10,000 rounds | 360° (manual and electrohydraulic) |

40°/sec | +20° to -10° (manual and electrohydraulic) |

25°/sec |

| 7.62mm M240 MG | Skate mount on loader's hatch | 1,400 rounds | 265° sector of fire (manual) |

-- | +65° to -35° (manual) |

-- |

| Aiming equipment | ||||||

| Gunner's primary and auxiliary sights for gunner; gunner's primary sight extension and CITV for commander | ||||||

| Rangefinder | ||||||

| Laser | ||||||

| Stabilizer | ||||||

| Azimuth and elevation | ||||||

| Night vision | ||||||

| TIS for gunner's primary sight and TC's extension, CITV for commander, image intensifying periscope AN/VVS-1(V)2 for driver | ||||||

| M1A2: Armor |

| Assembly |

| Welding |

| Hull |

| Rolled homogeneous steel and composite armor arrays |

| Turret |

| Rolled homogeneous steel and composite armor arrays |

| M1A2: Automotive | |||||

| Engine | Avco Lycoming AGT-1500; free shaft power gas turbine with two spool gasifier and recuperator | ||||

| Horsepower | Net: 1,232@3,000rpm Gross: 1,500@3,000rpm |

Torque | Net: 3,800 ft-lb@1,000rpm Gross: 3,934 ft-lb@1,000rpm |

Fuel capacity | 505gal 1,910L |

| Transmission | Allison X1100-3B, 4 ranges forward, 2 reverse | ||||

| Steering | Hydrostatic, T-bar | ||||

| Brakes | Hydraulic-mechanical, multiple disc | ||||

| M1A2: Suspension | ||

| Type | Road wheels | Track return rollers |

| Torsion bar | 7 independently sprung dual/track | 2 single/track |

| Drive sprockets | Idlers | Shock absorbers | 11-tooth rear drive | Dual compensating at front of track | On first 2 and last road wheels/track |

| M1A2: Track | |||||||

| T158 | |||||||

| Center guide, double pin, replaceable rubber pad | |||||||

| Width | 25" 64cm |

Pitch | 7.625" 19.37cm |

Shoes/track | 78 | Ground contact length | 180.1" 457.5cm |

| M1A2: Performance | |||

| Max level road speed | 42mph 68kph |

Max trench | 108" 274cm |

| Max grade | 60% | Max vertical obstacle | 42" 110cm |

| Min turning diameter | Pivot | Max fording depth | 48" 120cm |

| Cruising range | ~265mi ~426km |

||

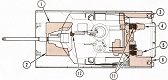

The M1A2 gave the tank commander an independent thermal viewer (CITV), allowing the crew to use hunter-killer tactics where the commander could scan for targets while the gunner was already engaging. The TC's weapon station in the M1A2 was changed to a non-rotating cupola with a manually-operated mount for the .50cal MG. The new cupola featured a lower number of larger vision blocks. The M1A2 was also fitted with upgraded armor and an intervehicular information system (IVIS), which allowed digital transmission of data between friendly units. A digital data bus and central processing unit assisted with the acquisition and dissemination of data, and the laser rangefinder was modified by Hughes Aircraft Company to permit usage at a rate of 1 pulse/second. Most M1A2s were created by modifying older M1 tanks.

The M1A2 SEP, or systems enhancement package, entered service in 2001 and featured improved armor, faster computer processors, color displays for the crew, a higher-resolution second-generation forward-looking infrared sight that replaces the TIS, and a thermal management system that replaced the auxiliary power unit in the turret bustle rack. The thermal management system provides air conditioning to keep the crew compartment under 95°F (25°C) and the temperature of the electronics under 125°F (52.7°C). The driver also received an integrated display in the SEP improvements.

TUSK upgrades were provided to the M1A2 as well. These kits were known as TUSK II, and the earlier M1A1 kits were retroactively named TUSK I. TUSK II had a new reactive armor layout with 7 tiles attached to the turret sides, and a new type of downward-angled reactive armor tile that was optimized for defeating explosively-formed projectiles from improvised explosive devices. The new reactive armor was designated XM32 ARAT 2. TUSK II also gave the TC an armored shield around his position with vision windows; a less extensive shield was designed for M1A1 TCs.

The M1A2 SEP V2 was fielded in 2008; the earlier M1A2 SEPs were then referred to as V1. The SEP V2 mounted better crew displays and an open digital architecture that could be upgraded without requiring extensive modification as new technologies emerge. The SEP V2 also had six additional heavy-duty batteries in the left rear hull where a fuel tank used to reside. A thermal rear-view camera was placed in the right taillight cluster, and a tank-infantry phone was mounted on the rear hull. The first M1A2 SEP V2 ECP1 (Engineering Change Proposal) tanks were introduced in 2014. The ECP1 provided improved armor; power supply solutions involving a more powerful generator, new turret slip ring, a battery management system, and a new power distribution system; a datalink between the tank's fire control system and its ammunition; an auxiliary power unit; and a multichannel joint tactical radio system replaced the single-channel ground and airborne radio system. The M153 common remotely operated weapon system-II (CROWS-II) was also mounted on the turret in front of the TC. This system provided a stabilized mount for a .50cal MG along with a daylight camera, thermal viewer, and laser rangefinder. It could be traversed through 360° and elevate from -20° to +60°. Four hundred .50cal rounds were stowed in its ammunition box. The CROWS once again provided the TC the ability to fire a machine gun from under armor.

On 4 October 2017, the first M1A2 SEP V3 was accepted. The M153A1 CROWS-low profile (LP) was 10" (25cm) shorter than the M153, and therefore offered the tank commander an easier time of seeing around it to the front. At the commander's station, the CROWS-LP featured a new daylight camera which could function as picture-in-picture to display different fields of view. Armor was again enhanced, and a lighter steel under-body blast kit was developed to replace the previous aluminum kit. Additional protective measures taken included redesigned blast-resistant seating and footrests for the crew, more numerous floor stiffeners, changes to internal structural supports including the turret basket supports, and assemblies to protect lower extremities. Energy-absorbing stanchions were installed beneath the turret basket, and the turret hydraulic manifold was installed on a crushable mount. Electrical power generation and propagation was enhanced by an improved amperage alternator, making the slip ring more robust, a battery monitoring system, and an enhanced hull power distribution system.