| M65: General | |||

| Date of first acceptance | 1952 | Total acceptances | 20 |

| Crew |

|

||

| M65: Dimensions | |||

| Weight (carriage and transporter units) | 166,638lbs 75,587.0kg |

Height in traveling position | 146" 371cm |

| Length in traveling position | 1,009¾" 2,564.77cm |

Width in traveling position | 123½" 313.7cm |

| Tread | 85½" 217cm |

Wheelbase for each transporter unit | 120" 305cm |

| Ground clearance | M249: 14" M250: 14½" M249: 36cm M250: 37cm |

||

| M65: Armament | |||

| Type | Mount | Traverse | Elevation |

| 280mm Gun M66 | Carriage M30 | Fine: 15° (7½° left and right; manual) Float: 360° (manual) |

+55° to 0° (manual and hydraulic) |

| Aiming equipment | |||

| Panoramic telescope M12A7C for gunner | |||

| M65: Armor |

| None |

| M65: Automotive | |||||

| Engine | M249: Continental AO-895-4 spec-3, M250: Continental AO-895-4 spec-4; 6 cylinder, 4 cycle, opposed gasoline | ||||

| Horsepower | Gross/engine: 375@2,800rpm | Torque | Gross/engine: 785 lb-ft@2,200rpm | Fuel capacity | 140gal/truck 530L/truck |

| Transmission | Manually-controlled full torque shifting, 3 speeds forward in each truck | ||||

| Steering | Hydraulic, steering wheels | ||||

| Brakes | Bendix-Westinghouse air, internal expanding | ||||

| M65: Suspension | |

| Type | Road wheels |

| Semi-elliptic leaf spring | 2/side/truck |

| M65: Performance | |||

| Max level road speed with gun and carriage | 35mph 56kph |

Max computed grade with gun and carriage | 30% |

| Min turning diameter of transport units | M249: 29' M250: 40' M249: 8.8m M250: 12m |

Max fording depth | 60" 150cm |

| Cruising range with gun and carriage | ~165mi, roads ~266km, roads |

||

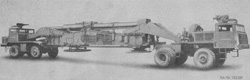

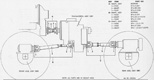

The M65 was developed in the early 1950s to give the US Army a nuclear-capable artillery system, and was colloquially known as the atomic cannon or "Atomic Annie." The system used the 280mm gun M66 on the carriage M30, and was provided with strategic mobility when loaded onto the detachable gun lifting trucks M249 and M250. Nuclear shells for smaller cannons as well as nuclear rockets were eventually developed, and these handier systems supplanted the ponderous M65 so that the system was retired by 1963.

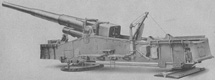

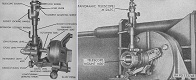

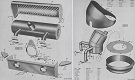

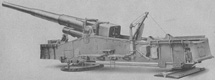

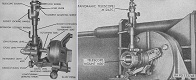

The 280mm gun M66 was manufactured by the Army's Watervliet Arsenal in New York, and weighed 42,050lb (19,070kg). It was a built-up type with the jacket shrunk onto the tube and the breech ring shrunk onto the breech end of the jacket. Forward of the breech ring, an extended portion of the jacket was smoothly finished and of uniform diameter to provide a bearing surface for recoil and to allow the tube to be retracted for travel. The tube's length was 41'9⅞" (12.748m), and its estimated accuracy life was 300 rounds.

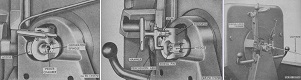

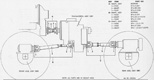

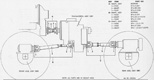

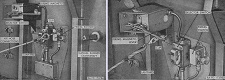

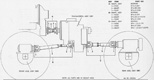

The carriage M30, manufactured by Pittsburgh's Dravo Corporation, was composed of three elements: top carriage, firing base, and float. The top carriage was a rigid rectangular structure upon which the gun and its operating mechanisms were mounted. The firing base and float constituted the bottom carriage upon which the gun recoiled and traversed, and were connected by longitudinal tie rods. Fifteen degrees of fine traverse were available with the ball pintle of the firing base and float, but 360° could be accomplished by lifting the float from the ground and traversing the firing base. A double recoil mechanism was used. The primary recoil mechanism M32, attached to the gun cradle below the gun tube, was an hydropneumatic type that used two recoil cylinders and a recuperator cylinder assembled with a manifold. The secondary recoil mechanism T81 or M33 was also hydropneumatic, and used a single recoil cylinder and recuperator cylinder attached to the firing base bolsters and connected to the elevating pinion shaft housing integral with the top carriage. This double mechanism permitted the gun tube and top carriage to be separately recoiling masses; the gun tube recoiled, and then moving the weight of the top carriage was also used to absorb recoil forces. An hydraulic power system powered by an off-carriage generator was found at the rear of the top carriage to assist with elevation and ramming.

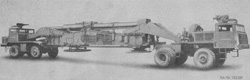

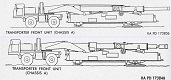

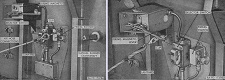

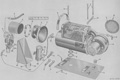

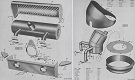

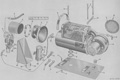

The carriage was able to be transported by mounting the front and rear to bespoke 4x4 lifting trucks manufactured by the Kenworth Truck Company. The front truck, or "A" unit, was designated as M249, and the rear, or "B" unit, as M250. Thirty-three of each type were built. Both featured hydraulic lifting forks, and each was powered by an AO-895-4 engine similar to that found in the M75 armored personnel carrier. The M249's cab was installed at the front, while that of the M250 was over the rear wheels. It took approximately 12 minutes to emplace the gun, and it could be placed in travel position in approximately 15 minutes.